Parts for Detroit Diesel 6V92 Non-Turbo - Exhaust Section

Loading...

Loading...-

Gasket, turbo exhaust inlet connection

8923580

Outside diameter 5.37", inside diameter 2.74"Price: $ -

-

-

-

-

-

-

-

-

-

-

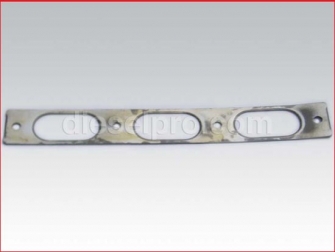

Detroit Diesel Threaded plate for marine manifold

5119926

3/4" Thread

Require 2 bolts, 5/16"-18 X 1 1/8"Price: $ -

-

Detroit Diesel 90 degree marine manifold elbow - 3/4inch thread

8924187

Elbow 90 degrees 3/4" thread -marine manifold

Price: $ -

-

-

-

Detroit Diesel Exhaust manifold gasket

23501170

Outside diameter 5.41", inside diameter 2.94"Price: $ -

-

-

-

-

-

Detroit Diesel Flexible metal exhaust pipe

5167174

Flexible metal exhaust pipe threaded, 4" diameter X 18" length

Price: $ -

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ -

Parts for Detroit Diesel 6V92 Non-Turbo – Exhaust Section

The Detroit Diesel 6V92 Non-Turbo engine is a workhorse of the two-stroke Detroit family, renowned for its simplicity, reliability, and long service life. Found in marine vessels, industrial machinery, and stationary power units, its naturally aspirated exhaust system is designed to deliver efficient scavenging and smooth gas flow without the assistance of a turbocharger. Every exhaust component—from gaskets and manifolds to elbows, flanges, and mufflers—plays a vital role in managing heat, pressure, and emissions.

At Diesel Pro Power , we supply all exhaust components engineered for the 6V92 Non-Turbo configuration. Each part is built to OEM standards for fit and durability and is fully supported by our technical team and fast worldwide delivery. Below is an expanded overview of the components available for this engine’s exhaust system.

Exhaust Gaskets and Sealing Components

A properly sealed exhaust system begins with the inlet connection. The exhaust inlet gasket prevents hot gases from leaking at the joint between the manifold and the pipe assembly. It is manufactured from high-temperature composite materials that resist thermal expansion and vibration. Whether the engine operates in a commercial truck, power generator, or marine vessel, a high-quality gasket ensures efficient exhaust flow, stable backpressure, and protection of nearby components from heat damage.

Cylinder Head to Manifold Gasket

Between each cylinder head and the manifold sits a head-to-manifold gasket , an essential barrier against exhaust leakage. This gasket maintains compression in each cylinder and prevents gases from escaping into the engine compartment. Its layered construction withstands repeated heating and cooling cycles, ensuring the 6V92 continues to perform smoothly across thousands of operating hours.

Proper installation requires cleaning both mating surfaces and applying uniform torque to prevent warping. Replacing old gaskets whenever the manifold is removed is recommended to maintain full sealing integrity.

Marine and Industrial Exhaust Manifolds

The marine exhaust manifold for the 6V92 Non-Turbo engine is a heavy-duty cast-iron component designed to collect and direct exhaust gases from each cylinder bank. Its internal passages are precision-cast for smooth flow and minimal restriction, while the exterior is treated to resist salt corrosion and high temperatures common in marine environments.

Used in a variety of Detroit Diesel configurations, this manifold offers superior strength and long-term reliability. In a marine setting, it is often paired with a wet-exhaust setup that allows seawater to cool the gases before discharge, protecting hoses and reducing noise.

Complementing the manifold are marine manifold plates that seal and regulate coolant or exhaust passages. A water outlet plate ensures consistent coolant flow, while threaded plates allow connection of elbows or fittings that route water or gases through the system.

A high-quality manifold plate gasket is used to prevent leaks between metal surfaces. These gaskets are resistant to both coolant and exhaust heat, maintaining a secure seal even after repeated service intervals.

Elbows, Flanges, and Fittings

90-Degree and 45-Degree Elbows

The 6V92 Non-Turbo system relies on a combination of 90-degree and 45-degree elbows to route gases efficiently from the manifold to the muffler or exhaust outlet.

-

90-degree elbows are ideal for installations requiring tight turns or compact routing.

-

45-degree elbows provide smoother gas redirection where space allows, minimizing turbulence and maintaining gas velocity.

Constructed from marine-grade materials, these elbows resist corrosion and maintain strength under thermal expansion. Threaded connections ensure secure fitment without exhaust leaks, even under constant vibration.

Industrial Flanges and Gaskets

In stationary or industrial applications, the exhaust manifold connects to downstream piping through a 4-inch flange . This robust connector ensures a stable joint that withstands vibration and exhaust pressure. The flange gasket —made of flexible graphite composite—provides a tight seal while accommodating thermal movement. Together, they prevent exhaust leaks, optimize backpressure, and extend the lifespan of connected components.

Manifold Hardware

Every exhaust manifold assembly relies on precise hardware to maintain a gas-tight seal under extreme conditions.

-

Manifold Studs: Threaded fasteners that secure the manifold to the cylinder head. They must handle high tensile loads and frequent temperature fluctuations.

-

Manifold Crabs (Clamps): Curved retainers that distribute clamping pressure evenly across the manifold flange to prevent warping.

-

Washers and Nuts : Hardened steel washers prevent galling and distribute torque evenly, while self-locking nuts ensure a secure connection that resists vibration loosening.

When servicing the exhaust system, replacing old or corroded hardware is essential to maintain correct alignment and pressure distribution.

Exhaust Insulation

Manifold Insulation Tape – 3" and 4" Widths

Insulating the manifold and exhaust piping is crucial in marine and industrial engine rooms. Manifold insulation tape , available in 3-inch and 4-inch widths, reduces surface temperatures, preventing burns and improving ambient air conditions around the engine.

The fiberglass-based material withstands temperatures well above typical exhaust operating levels, helping maintain exhaust velocity for efficient gas evacuation. Wrapping the manifold and elbows with insulation also reduces heat transfer to adjacent systems such as fuel lines or cooling hoses.

Mufflers and Exhaust Caps

For stationary 6V92 Non-Turbo engines used in generators or industrial machinery, the 4-inch muffler provides noise suppression and smooth exhaust flow. Its heavy-gauge steel housing and internal baffle design reduce sound levels without restricting pressure, ensuring quiet and efficient operation. Both inlet and outlet ports are threaded for easy connection to flanges or flexible hoses.

Proper muffler selection contributes to overall system performance. A mismatched muffler can create excessive backpressure, reducing power and fuel efficiency. Diesel Pro Power’s mufflers are engineered to maintain the ideal balance of silencing and flow.

Muffler Caps

To protect engines when they are idle, muffler caps are installed over exhaust outlets. Available in multiple diameters—typically ranging from 3 to 5 inches—these hinged or spring-loaded caps prevent water, dust, or debris from entering the exhaust line.

-

Smaller caps (around 3 inches) are used on auxiliary or generator setups.

-

Mid-size caps (3½–4½ inches) suit standard industrial or marine engines.

-

Larger 5-inch caps protect full-size propulsion engines such as the 6V92.

Each cap is made from corrosion-resistant metal for durability in outdoor or marine environments. They automatically lift when the engine starts, allowing unrestricted exhaust flow.

Flexible Exhaust Hose

The flexible metal exhaust hose connects rigid manifold or muffler sections and compensates for vibration and thermal expansion. On a 6V92 Non-Turbo setup, this 4-inch diameter hose allows for slight movement without causing stress on manifold joints or flanges.

It is constructed from interlocking stainless-steel segments that maintain structural integrity under heat and pressure. The flexibility also simplifies installation in tight engine compartments and reduces transmitted vibration, extending the life of connected exhaust components.

Temperature Switch and System Monitoring

An engine temperature switch is often installed within the exhaust or coolant system to monitor operational heat levels. When the temperature exceeds approximately 205°F, the switch closes, triggering an alarm or gauge signal. This safety feature helps operators detect overheating early, preventing damage to exhaust components and engine internals.

The switch uses a standard NPT thread for compatibility across Detroit Diesel, Cummins, and Caterpillar engines, providing versatile monitoring options across mixed fleets.

Engine Paint and Corrosion Protection

To maintain factory appearance and protect against rust, Detroit Green paint is available for refinishing manifolds, mufflers, and external engine surfaces. The paint is formulated to resist heat and oil, ensuring lasting protection in both marine and industrial environments. Proper coating after exhaust maintenance or replacement keeps the engine bay clean, professional, and corrosion-free.

Monitoring and Instrumentation

Maintaining proper exhaust temperature and engine condition is easier with mechanical and electric gauges . Diesel Pro Power offers:

-

Mechanical gauges for direct readings with or without alarms.

-

Electric gauges in 12-volt or 24-volt configurations for remote monitoring.

Integrating these gauges into a 6V92 Non-Turbo setup allows real-time tracking of oil pressure, temperature, and exhaust performance—key metrics for maximizing efficiency and longevity.

Why Buy Detroit Diesel 6V92 Exhaust Parts from Diesel Pro Power

Proven Global Experience

With over 40,000 satisfied customers worldwide , Diesel Pro Power is the preferred source for Detroit Diesel parts. Our extensive catalog covers every major component of the 6V92 Non-Turbo engine’s exhaust system, from manifold studs to mufflers. Each product is designed or selected to meet OEM quality standards and tested for durability under real-world operating conditions.

Expert Support and Reliable Fulfillment

Our experienced technical team understands the nuances of Detroit Diesel two-stroke engines. We offer personalized guidance to ensure each customer gets exactly the parts required for their specific configuration. Orders ship quickly, with real-time tracking and international coverage to more than 200 countries.

Built for Performance and Longevity

Every exhaust component we supply—gasket, manifold, elbow, or flange—is engineered to withstand the heat, vibration, and corrosion associated with marine and industrial environments. When paired with proper maintenance practices, these components contribute to lower emissions, quieter operation, and extended engine life.