Parts for Detroit Diesel 471 Turbo

-Select Parts Category

Loading...

Loading...- 1

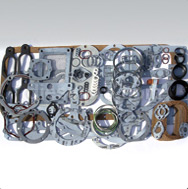

Engine Overhaul Kit

Engine Overhaul Kit - 2

Cylinder head

Cylinder head - 3

Injector

Injector - 4

Fuel Pump

Fuel Pump - 5

Engine Water Pump

Engine Water Pump - 6

Marine Water Pump

Marine Water Pump - 7

Blower

Blower - 8

Turbo

Turbo - 9

Oil Pump

Oil Pump - 10

Gauges

Gauges - 11

Crankshaft

Crankshaft - 12

Connecting Rod

Connecting Rod - 13

Camshaft

Camshaft - 14

Exhaust

Exhaust - 15

Gasket

Gasket - 16

Switch & Solenoid

Switch & Solenoid - 17

Manuals & Tools

Manuals & Tools - 18

Starter & Alternator

Starter & Alternator - 19

Cylinder Kit

Cylinder Kit - 20

Hose, Clamp

Hose, Clamp - 21

Fuel Filter

Fuel Filter - 22

Oil Filter

Oil Filter - 23

Engine, Block

Engine, Block - 24

33C Marine Cable (3/16")

33C Marine Cable (3/16") - 25

43C Marine Cable (1/4")

43C Marine Cable (1/4") - 26

Industrial Cable

Industrial Cable - 27

Paint & Sealant

Paint & Sealant - 28

Power Take-off

Power Take-off

Detroit Diesel 471 Turbocharged Engine Specifications & Applications Of This Engine

Introduction to the Detroit Diesel 471 Turbocharged Engine

The Detroit Diesel 471 Turbo engine is a power-enhanced variant of the legendary Series 71 platform—an inline 4-cylinder, two-stroke diesel engine upgraded with a turbocharger to increase air intake, combustion efficiency, horsepower, and torque output.

While the naturally aspirated versions of the 471 (both 2-valve and 4-valve) are appreciated for their simplicity, the turbocharged configuration offers increased performance for heavier loads and higher-demand applications without drastically changing the core reliability of the engine. It’s especially popular in marine, generator, and industrial applications where more output is needed from the same compact block.

At Diesel Pro Power , we support operators and mechanics by providing aftermarket parts built to last. Our comprehensive catalog includes everything from complete overhaul kits to turbochargers, injectors, gaskets, heads, and marine accessories—all available online, backed by warranty, and ready to ship worldwide.

Key Specifications of the Detroit Diesel 471 Turbo Engine

Engine Architecture

-

Engine Series: Detroit Diesel 71 Series

-

Model: 471 Turbocharged

-

Cylinders: 4 (Inline Configuration)

-

Aspiration: Turbocharged (no intercooler unless modified)

-

Cycle Type: Two-Stroke Diesel

-

Valvetrain Options: 4 valves per cylinder (most turbocharged 471s use 4-valve heads)

-

Firing Order: 1-3-4-2

-

Compression Ratio: 16.5:1 (lower than NA for turbo setup)

Power and Performance

-

Horsepower Range: 160 – 200 HP (depending on injector size and RPM)

-

Torque Output: Approx. 400–500 lb-ft at rated speeds

-

Rated RPM: Typically 2,100 RPM for marine, 1,800 RPM for industrial

-

Turbo Type: Fixed geometry, exhaust-driven

-

Governor Type: Mechanical (variable or limiting speed)

Internal Engine Dimensions

-

Bore: 4.25 inches (108 mm)

-

Stroke: 5.00 inches (127 mm)

-

Displacement: 284 cubic inches (4.65 liters)

-

Engine Oil Capacity: ~7.5 gallons (28.4 liters)

-

Coolant Capacity: ~6.5 gallons (24.6 liters)

-

Operating Oil Pressure: 40 – 60 PSI at rated speed

-

Operating Temp Range: 170°F – 195°F

-

Max Coolant Temperature: 200°F

Turbocharger Details

-

Exhaust Drive Configuration

-

Mounted on Exhaust Manifold

-

Non-intercooled (Stock)

-

Increased Air Mass = More Fuel Efficiency & Power

Performance Advantages of the Turbocharged 471

1. Increased Power Output

The 471 Turbo delivers up to 25% more horsepower compared to its naturally aspirated counterpart. This allows smaller boats and compact machinery to move heavier loads or achieve higher cruising speeds.

2. Better Fuel Economy at Load

Though the turbo adds fuel under boost, it improves fuel efficiency under full-load conditions due to more complete combustion and improved intake flow.

3. Improved Altitude and Heat Tolerance

Turbocharged engines maintain performance better at high altitudes and in hot climates , making the 471 Turbo ideal for workboats operating in tropical or mountainous environments.

4. Torque at Lower RPM

The addition of a turbo helps the 471 produce more torque down low, allowing better maneuverability under load in marine applications like tugboats or crabbers.

Marine Applications of the 471 Turbocharged Engine

This engine has been a reliable powerplant across diverse marine operations where higher output is needed in tight engine room spaces.

Recreational and Fishing Boats

-

Trawlers and Yachts: Popular among long-range trawlers and commercial yachts retrofitted for power cruising.

-

Sport Fishing Boats: Used for increased speed, range, and reliability on offshore trips.

-

Crabbing & Lobstering Vessels: Offers responsive throttle control and dependable push for hauling traps or nets.

Commercial Workboats

-

Tugboats and Push Boats: Reliable for low-speed torque, harbor pushing, and barge maneuvering.

-

Landing Craft: Ideal for military and logistics vessels needing strong torque in shallow waters.

-

Harbor Utility Boats: Used in mooring, pilot boat, and maintenance fleet vessels.

Government & Military Craft

-

Coast Guard Auxiliary Boats

-

River Patrol Craft

-

Amphibious Military Landing Vessels

Industrial Applications of the 471 Turbo Engine

Beyond the waterfront, the turbocharged 471 has also been a solid performer in demanding onshore applications:

-

Power Generators: Used in higher-capacity units needing constant power output above 80 kW.

-

Water Pumps: Turbo increases performance in irrigation, flood control, and emergency systems.

-

Mining Equipment: Rock crushers and conveyor systems benefit from increased power and durability.

-

Oilfield Service Equipment: High load, continuous duty tools like drill rig generators or pipe handling systems.

-

Construction Equipment: Cranes and earthmovers where long duty cycles under heavy loads are common.

Popular Injector Sizes for the 471 Turbo Engine

Injector size significantly influences performance and fuel consumption. Turbocharged 471 engines typically use larger injectors:

-

N60: Approx. 160 HP

-

N65: Approx. 170 HP

-

N70: Approx. 180 HP

-

N75: Approx. 190–200 HP

We stock all common Detroit injectors in matched flow sets ready to drop in. Always match injectors with governor type and turbo sizing.

Additional Resources

Marine Detroit Diesel 4-71 Component Maintenance Life

Practical Guide To Servicing Your Detroit Diesel 71 Series Inline (271, 371, 471, & 671 ) – Part 1

Engine Components and Their Roles (Covering Detroit Diesel 271, 371, 471, 671 Engines)

Key Maintenance Procedures (Covering Detroit Diesel 271, 371, 471, 671 Engines)

Assembly and Disassembly Guidelines (Covering Detroit Diesel 271, 371, 471, 671 Engines)

Safety Protocols for Technicians (Working On Detroit Diesel 271, 371, 471, 671 Engines)

Torque Specifications And Wear Limits (Covering Detroit Diesel 271, 371, 471, 671 Engines)

AIR SCAVENGING AND BLOWER SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Best Practices for Keeping Air Intake and Exhaust Systems Clean For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Cleaning and Inspection Processes For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Safe Cleaning Procedures Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Critical Inspection Points For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Valve and Injector Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Checking Valve Clearance and Injector Timing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Tools and Equipment For Maintaining Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Detailed Overhaul Process For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Common Troubleshooting Tips For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Fuel Lines For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Exhaust Manifold For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Throttle Controls For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

DISASSEMBLY OF AIR BOX COVERS FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Disassembly Of The Blower For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Removing Air Box Drains For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

REMOVING THE VALVE ROCKER COVER ON A DETROIT DIESEL 71 SERIES INLINE ENGINE (271, 371, 471, 671)

Disassembling The Air Cleaner & The Air Shutdown Housing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Torque Specifications Of 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Components For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Key Components of the Oil Pump and Model-Specific Variations (271, 371, 471, 671)

INSIGHTS FROM THE DETROIT DIESEL 71 SERIES INLINE ENGINE MANUAL VOLUME 2 (271, 371, 471, 671)

LUBRICATION SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Disassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Reassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Oil Filters For Detroit Diesel 71 Series Inline Engines (271,371, 471, 671)

LUBRICATING OIL PRESSURE REGULATOR FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Oil Cooler For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Oil Pan For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Ventilating System for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Oil Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Radiator Cooling For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Cooling System and Heat Exchanger For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Cooling System Configurations For 71 Series Inline Engines (271, 371, 471, 671)

Types of Coolant for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Chemicals & Coolant For Your Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Maintaining The Heat Exchanger Core For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Guidelines for Coolant For Detroit 71 Series Inline Engines (271, 371, 471, 671)

Introduction to the Water Pump System for the 71 Series Inline Engine (271, 371, 471, 671)

Disassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Reassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline (271, 371, 471, 671)

Freshwater Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Raw Water Pump Maintenance (Marine Application) For 71 Series Inline Engines (271, 371, 471, 671)

Disassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Reassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Thermostat Operation For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

SYSTEMATIC APPROACH TO TROUBLESHOOTING DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Cooling System Troubleshooting For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Troubleshooting Tips for Improved Efficiency In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Summary of Troubleshooting and Specifications In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Detroit Diesel 271,371,471,671 Inline Engine Tune Up Guide

FAQ From Detroit Diesel 71 Series Inline Engine Service Manual (271, 371, 471, 671)

Disassembly Turbocharger (If Equipped) For Detroit Diesel 71 Series Inline Engines (471, 671)

Disassembly Of Turbochargers For Detroit Diesel 71 Series Inline Engines – (471, 671)