Parts for Detroit Diesel 12V71 Turbo - Exhaust Section

Loading...

Loading...-

-

Detroit Diesel Marine water cooled manifold for 6-71,12V71

8921704

New, Requires 1-inch thread fittings

Price: $ -

Detroit Diesel Head to Manifold Gasket for 6-71 and 12V71

5120223

Click on + Pictures below to see how many are needed per engine

Price: $ -

Detroit Diesel Adaptor - turbo riser

5130339

New - Inner diameter 4”, Outer diameter 6.25”, Height 1.125

Price: $ -

Detroit Diesel Head to Manifold Gasket for 471, 671, 8V71, 12V71, 16V71, 8V92, 16V92

5120224

Click on + Pictures below to see how many are needed per engine

Price: $ -

Detroit Diesel Gasket for marine manifold flange

23504701

Outside diameter 6.25", inside diameter 4.25"

Price: $ -

Detroit Diesel Turbo riser gasket

8923492

Inner width 2”, Inner Length 3.75”, Outer width 3.75”, Outer Length 5.5”

Price: $ -

Detroit Diesel Gasket for marine manifold 12V71, 6V92, 8V92, 12V92, 16V92

23515227

Outside diameter 6.80", inside diameter 4.25"Price: $ -

-

-

-

-

-

-

-

-

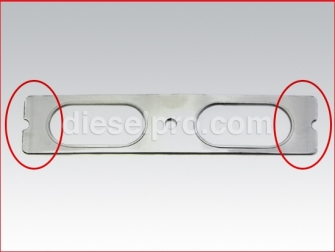

Detroit Diesel Threaded plate for marine manifold

5119926

3/4" Thread

Require 2 bolts, 5/16"-18 X 1 1/8"Price: $ -

-

Detroit Diesel 90 degree marine manifold elbow - 3/4inch thread

8924187

Elbow 90 degrees 3/4" thread -marine manifold

Price: $ -

-

Detroit Diesel Gasket, marine manifold flange spacer

5101914

Outside diameter 6.25", inside diameter 3.50"Price: $ -

-

-

Cap for Detroit Diesel engine muffler

P270543

6" for industrial engines.

Pipe Outside Diameter: 5.98" | 15.18 cm

Price: $ -

Detroit Diesel Flexible metal exhaust pipe

5167174

Flexible metal exhaust pipe threaded, 4" diameter X 18" length

Price: $ -

DP-6 X 18 Flexible metal exhaust pipe for Detroit Diesel engine

6 X 18

Flexible metal exhaust hose 6 x 18"Price: $ -

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ -

Parts for Detroit Diesel 12V71 Turbo – Exhaust Section

The Detroit Diesel 12V71 Turbo is one of the most powerful and iconic engines in the Series 71 family. Built for reliability and performance, this V12 two-stroke engine has powered countless vessels, industrial machines, and heavy-duty applications around the world. The turbocharged configuration enhances efficiency, boosting both horsepower and torque while maintaining the rugged dependability that Detroit Diesel is famous for.

Keeping a 12V71 Turbo in top condition means maintaining a clean, properly functioning exhaust system. Each component—from the manifolds and risers to the gaskets and flexible metal hoses—plays a vital role in heat management, turbocharger performance, and exhaust gas evacuation. Below is a detailed look at the full catalog of exhaust components available for the Detroit Diesel 12V71 Turbo, followed by a breakdown of how each part contributes to optimal engine operation.

Detroit Diesel Riser Connector for 12V71 Turbo Engines

The riser connector links the exhaust riser to the rest of the exhaust system, managing both backpressure and exhaust flow. In marine and stationary applications, it ensures the proper direction of exhaust gases away from the turbocharger and prevents seawater intrusion into the turbo and engine cylinders.

Made from high-grade materials to withstand marine heat and corrosion, the riser connector for the 12V71 Turbo helps maintain exhaust gas velocity and flow balance between cylinders. A failed riser connection can lead to loss of boost pressure, overheating, and potential turbocharger damage. Diesel Pro Power offers new riser connectors designed specifically for Detroit Diesel marine applications, ensuring a direct fit and long-term reliability.

Detroit Diesel Marine Water-Cooled Exhaust Manifold

The marine water-cooled manifold for the 12V71 Turbo engine combines durability with cooling efficiency. Designed to circulate raw or jacket water around the manifold housing, it lowers exhaust gas temperatures and prevents overheating of adjacent components.

This manifold is made for 6-71 and 12V71 engines, offering excellent compatibility across Detroit Diesel’s most common marine setups. The design requires 1-inch thread fittings for water inlet and outlet connections. The water-cooled feature is crucial in marine environments where compact engine rooms generate high thermal loads.

A new manifold from Diesel Pro Power provides a clean, leak-free fit, ensuring efficient exhaust flow and improved heat dissipation for optimal performance under heavy load conditions.

Detroit Diesel Head to Manifold Gaskets

High-quality gaskets are essential in sealing exhaust connections between the cylinder head and manifold. The Detroit Diesel 12V71 Turbo uses multiple head-to-manifold gaskets to ensure tight seals that can withstand both temperature fluctuations and pressure variations.

Diesel Pro Power supplies gaskets that are precisely cut to OEM dimensions, using durable composite materials that resist blowout and corrosion. The correct number of gaskets per engine must be installed to ensure proper alignment and sealing—an often-overlooked detail that can prevent exhaust leaks and improve overall turbo efficiency.

Detroit Diesel Turbo Riser Adaptor

The turbo riser adaptor serves as the connection point between the turbocharger outlet and the exhaust riser. It is machined for a perfect fit and allows smooth transition of hot gases from the turbo to the manifold riser assembly.

Featuring a 4” inner diameter, 6.25” outer diameter, and a height of 1.125”, this adaptor helps maintain consistent exhaust flow and pressure balance—key factors in maintaining boost performance and turbocharger longevity. A poorly fitted adaptor can cause misalignment, leading to vibration, leaks, and eventual failure of the turbo or riser connection. Diesel Pro Power ensures exact-fit adaptors that meet or exceed OEM standards for marine and industrial Detroit Diesel applications.

Detroit Diesel Marine Exhaust Gaskets

Various gasket types are used throughout the 12V71 Turbo exhaust system, including flange gaskets, riser gaskets, and manifold water outlet gaskets. Each gasket prevents leaks of exhaust gases or cooling water, ensuring proper thermal management and safety within the engine room.

For marine engines, Diesel Pro Power’s gaskets are made from heat-resistant composite and reinforced metal layers that provide long-lasting sealing capability under extreme temperature cycles. Whether you’re replacing a flange gasket or a turbo riser gasket, these components are engineered for a perfect seal and long operational life.

Detroit Diesel Marine Manifold Flange and Spacer Gaskets

The manifold flange and spacer gaskets act as interfaces between the manifold outlet and exhaust piping or elbows. On turbocharged 12V71 engines, these gaskets ensure that high-pressure exhaust gases are contained within the system without escaping into the engine compartment.

Diesel Pro Power’s flange gaskets have precise internal and external diameters to match OEM standards—6.25” outside and 4.25” inside—offering superior sealing performance even under sustained high-temperature conditions.

Manifold Insulation Tape

Thermal insulation is critical in high-output turbocharged engines like the 12V71 Turbo. Manifold insulation tape minimizes radiant heat loss and protects surrounding components from extreme temperatures.

Diesel Pro Power offers both 3-inch and 4-inch wide insulation tapes, each 100 feet long and 1/8-inch thick. These tapes wrap around manifolds and exhaust risers to maintain surface temperatures, enhance safety in confined spaces, and prevent burns or damage to nearby hoses and wiring. High-quality insulation materials also reduce engine room heat buildup, improving ambient air conditions and ventilation efficiency.

Manifold Hardware: Studs, Crabs, Washers, and Nuts

A secure manifold installation relies on durable hardware designed to handle the constant expansion and contraction of metal under heat.

-

Studs (7/16" - 14/20 x 2.10") provide the foundation for attaching the manifold to the engine block.

-

Manifold crabs act as stabilizing brackets that distribute pressure evenly across the manifold.

-

Washers and nuts complete the assembly, ensuring a uniform clamp load that prevents leaks.

Diesel Pro Power supplies all manifold fasteners and supports made to factory specifications, so maintenance crews can replace worn or corroded parts with confidence that the new components will hold up under long-term marine service conditions.

Detroit Diesel Marine Manifold Water Outlet Plates and Threaded Caps

Water outlet plates and threaded caps are crucial to controlling coolant flow through water-jacketed manifolds. These plates ensure even water distribution, while threaded caps allow for service access or the attachment of temperature sensors and elbows.

Diesel Pro Power provides OEM-grade plates and ¾” threaded caps built to resist corrosion from seawater and coolant exposure. Each unit ensures leak-free operation, maintaining the balance between exhaust cooling and backpressure regulation.

Marine Manifold Elbows (45° and 90° Configurations)

Exhaust elbows redirect exhaust gases efficiently while minimizing turbulence and maintaining system backpressure. The Detroit Diesel 12V71 Turbo uses both 45° and 90° marine manifold elbows, depending on vessel configuration.

-

90° elbows (1” and ¾” threads) are ideal for tight installations.

-

45° elbows provide smoother transitions for optimized exhaust flow.

Each elbow is precision-machined to prevent leaks and resist corrosion in saltwater environments. Diesel Pro Power’s elbows meet strict marine-grade standards and are available in multiple thread sizes to suit all Detroit Diesel 12V71 Turbo configurations.

Muffler Caps for Detroit Diesel 12V71 Turbo

Muffler caps serve as protective covers that prevent water, debris, and insects from entering exhaust outlets when the engine is off. For 12V71 Turbo engines, caps are available in 4.5”, 5”, and 6” diameters, ensuring proper fit for a range of marine and industrial setups.

These caps are made from corrosion-resistant materials and designed for smooth operation in harsh marine environments. A simple yet essential component, muffler caps protect internal exhaust components and help extend the lifespan of the entire system.

Flexible Metal Exhaust Hoses

Flexibility is vital in marine exhaust systems where vibration, motion, and heat expansion occur constantly. Flexible metal exhaust hoses absorb these stresses, preventing cracking or fatigue in rigid pipe sections.

Diesel Pro Power supplies heavy-duty flexible exhaust hoses in three standard sizes for 12V71 Turbo installations:

-

4” x 18” – ideal for compact or auxiliary setups.

-

6” x 18” – for medium exhaust flow rates.

-

8” x 18” – for high-output exhaust lines on dual turbo or industrial configurations.

Each hose features reinforced construction that maintains structural integrity under pressure, high temperatures, and vibration, ensuring reliable service in even the most demanding environments.

Temperature Switch for Detroit Diesel Engines

To protect the engine from overheating, the temperature switch activates at 205°F. This simple but essential part ensures that the cooling system functions correctly, triggering alarms or shutdown mechanisms if temperature limits are exceeded.

The ½” NPT thread allows universal compatibility across Detroit Diesel, Cummins, and Caterpillar engines. It is especially useful in turbocharged marine engines where heat management is critical.

Detroit Green Paint for Engine Restoration

A finishing touch that many restoration and maintenance professionals appreciate, Diesel Pro Power offers authentic Detroit Green Paint for Series 71 engines. Beyond aesthetics, the coating provides corrosion protection against moisture, salt, and oil exposure—making it perfect for marine or industrial applications.

Why Buy Detroit Diesel 12V71 Turbo Exhaust Parts from Diesel Pro Power

Trusted by Over 40,000 Satisfied Customers

Diesel Pro Power is the world’s leading online source for Detroit Diesel marine and industrial engine parts. With more than 40,000 satisfied customers across 180+ countries, the company has earned its reputation as a trusted supplier for commercial operators, shipyards, and individual mechanics alike.

Precision-Engineered for Detroit Diesel Engines

Every part offered—from gaskets to manifolds—is built to meet or exceed OEM specifications for fit, material quality, and durability. Diesel Pro Power ensures that each product is compatible with the 12V71 Turbo engine, reducing installation time and minimizing downtime for vessel owners.

Fast Shipping and Global Support

All items listed are in stock and ready for immediate shipment. Diesel Pro Power specializes in fast international delivery with accurate tracking, so customers can confidently plan maintenance schedules.

Expert Technical Assistance

For over three decades, Diesel Pro Power has supported Detroit Diesel operators with expert technical help, including installation guidance, torque specifications, and compatibility verification. Their multilingual team ensures customers worldwide receive accurate, clear support.

Comprehensive Inventory for Detroit Diesel 12V71 Turbo

From the smallest gasket to the largest manifold assembly, Diesel Pro Power provides a one-stop source for complete exhaust system overhauls. All products are quality-tested and backed by responsive customer service that prioritizes your uptime.