Cummins QSC Parts - Rebuild Kit Section

Loading...

Loading...-

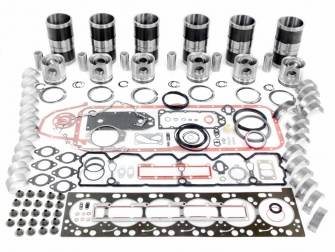

Cummins Rebuild Kit QSC 8.3 - 1 piece piston

IFK0318-QSC

For engines with CPL #s 8088, 8153, 8203

Price: $ -

Cummins Rebuild Kit QSC 8.3 - 1 piece piston

IFK5190-QSC

For engines with CPL #s 1632, 2722, 8626, 8627, 8630, 8632, 8633, 8634, 8635, 8636, 8637, 8639, 8745, 8746.

Price: $ -

Nozzle to cool pistons Cummins 6C, 6CT, ISC, QSC, L10, ISL, QSL

3928031

Size 1.22" long. Engine requires 6 per engine, for articulated pistons

Price: $ -

Nozzle to cool pistons for Cummins 6C, ISC, QSC, L, ISL, QSL

3905928

Size 1.73". 6 per engine required

Price: $ -

-

Cummins Crankshaft Seal Kit - Front

3925343

Includes the seal and sleeve, for non-automotive applicationsPrice: $ -

-

Cummins Crankshaft Seal Kit - Rear

4955372

Includes the seal (double lip) and sleeve, for engines with wet clutch housingPrice: $ -

Cummins Oil Filter

3401544

Spin-on type, 4.65" diameter, 11.69" height, thread size: 2 1/4" - 12 UNPrice: $ -

-

-

-

-

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ -

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $

Cummins QSC Overhaul Kits by CPL Number

The Cummins QSC 8.3 engine is a powerful, electronically controlled, six-cylinder diesel engine used widely in marine, industrial, and heavy equipment applications. Designed for performance and durability, it operates in demanding environments where regular maintenance and periodic overhauls are essential to extend service life and ensure peak reliability.

Diesel Pro Power offers complete overhaul kits for Cummins QSC engines, grouped by CPL (Control Parts List) numbers to ensure precise compatibility. Our kits are ideal for complete engine rebuilds and come equipped with the most reliable, OEM-grade components available for your engine’s specifications.

Overhaul Kit for Cummins QSC Engines — Compatible with CPL 8088, 8153, 8203

This rebuild kit is engineered for Cummins QSC engines with one-piece pistons and rear gear train design. These engine configurations are frequently used in applications such as marine propulsion systems, power generation, and industrial equipment.

Kit Includes:

-

One-piece pistons (standard size or optional oversize available)

-

Piston rings

-

Cylinder liners

-

Connecting rod bearings

-

Main bearings

-

Thrust washers

-

Full gasket set

-

Camshaft bushings (if required)

-

Injector o-rings and seals

Compression Ratio: This kit supports configurations with a standard compression ratio of approximately 16.3:1 , which is ideal for high-torque, mid-speed engine operation. A compression ratio of 16.3:1 strikes a balance between fuel efficiency and combustion force, promoting durability and smoother performance in heavy-duty service environments.

Overhaul Kit for Cummins QSC Engines — Compatible with CPL 1632, 2722, 8626–8746 Series

This overhaul kit fits QSC 8.3 engines configured with one-piece pistons and optimized electronic control systems. These CPLs are typically seen in newer marine and industrial diesel applications and are designed for improved emissions control and fuel mapping.

Kit Includes:

-

One-piece pistons

-

Chrome-plated piston rings

-

Hardened cylinder liners

-

Rod and main bearings

-

Full upper and lower gasket sets

-

Seals for injectors and fuel system

-

Oil seals and wear rings

-

Cylinder head seals

Compression Ratio: Engines in this CPL group also operate at approximately 16.3:1 compression ratio. This consistent design allows reliable combustion with cleaner emissions and a controlled power output that supports marine propulsion and auxiliary power units.

Why Compression Ratio Matters in QSC Overhauls

The compression ratio defines how much the air in the cylinder is compressed before fuel injection. A 16.3:1 compression ratio means the air-fuel mixture is compressed to about 1/16th of its original volume. This high ratio allows diesel engines to ignite fuel through compression alone, providing efficient energy conversion and better torque output.

In marine and industrial contexts, maintaining the correct compression ratio ensures optimal fuel combustion, reduced soot and emissions, and maximum cylinder pressure for longevity and performance.

Essential Components for Cummins QSC Engine Rebuilds

In addition to the overhaul kits, several auxiliary components are crucial to completing a successful engine rebuild. These components ensure proper sealing, oiling, cooling, and protection of your internal engine parts.

Piston Cooling Nozzles

Piston cooling nozzles are installed to spray engine oil directly onto the underside of the piston. This helps dissipate heat generated during combustion and prevents piston deformation or scoring. Cummins QSC engines typically require six nozzles per engine , depending on piston type (articulated or one-piece).

Available Sizes:

-

1.22" for articulated piston configurations

-

1.73" for one-piece piston configurations

Replacing these nozzles during a rebuild is essential to preserve piston integrity and prevent premature wear, especially in engines operating under continuous or heavy load.

Crankshaft Seal Kits (Front & Rear)

Crankshaft seals are critical for maintaining oil pressure and keeping contaminants out of the engine’s rotating assembly. Diesel Pro Power offers front and rear crankshaft seal kits specifically designed for QSC engines.

-

Front Seal Kits: Available for both automotive and non-automotive applications, including variants with sleeves and dust shields.

-

Rear Seal Kits: Designed for engines with standard or wet clutch housings, these kits include double-lip designs and sleeves for reliable sealing under high pressure.

Installing new seal kits as part of your overhaul ensures leak-free operation and protects your crankshaft bearings from oil starvation and contamination.

Filters for Fuel, Oil, and Water Separation

Replacing filters is a non-negotiable part of any overhaul. Diesel Pro Power offers a full range of fuel and oil filters compatible with Cummins QSC engines:

-

Spin-On Fuel Filters : Available in standard and extended lengths, with various thread types and filtration micron ratings.

-

Fuel/Water Separators: Essential for marine environments, these filters help prevent water from entering the injection system.

-

Oil Filters: Spin-on types with heavy-duty media support efficient oil flow and debris capture, helping extend engine life after rebuild.

All filters are designed to OEM specifications for flow rate, capacity, and efficiency.

Engine Rebuild Tools for Cummins QSC

To execute a thorough engine rebuild, specific tools are needed. We carry professional-grade tools designed for Cummins engine service:

Feeler Gauge Set

Used for calibrating valve lash settings after cylinder head installation. Proper valve clearance is essential for combustion efficiency and camshaft protection.

Piston Ring Assembly Tool

Ensures accurate installation of piston rings onto pistons without distortion or damage. Using this tool prevents ring breakage and maintains cylinder wall conformity.

Fuel Filter Wrench

Adjustable filter wrench designed to remove or install Cummins spin-on fuel filters without slippage or crushing the canister.

Oil Filter Wrench

Sized specifically for Cummins oil filters; helps ensure tight installation to manufacturer torque spec and easy removal without filter distortion.

Additional Components That Support Engine Life

Radiator Cleaner

A clean cooling system is vital for regulating engine temperature. Use a radiator cleaner to flush debris and scale buildup from the system before initial start-up.

Temperature Switch

This sensor triggers alerts or cooling actions when the engine exceeds safe operating temperatures. Common in marine systems where overheat prevention is essential.

Vibration Isolators

Used in marine and industrial settings, these rubber mounts reduce vibration transfer between engine and frame. Each QSC engine typically uses four isolators .

Why Choose Diesel Pro Power for Cummins QSC Overhaul Kits?

With over 40,000 satisfied customers , Diesel Pro Power has become a trusted source for diesel engine rebuild components. Every kit we sell is built to match OEM performance, with components selected for durability, compatibility, and rebuild success.

We offer:

-

CPL-specific kit groupings for accurate fitment

-

Kits that support OEM compression ratios and specifications

-

All supporting components in one place — no need to shop around

-

Fast global shipping and reliable customer support

When Should You Rebuild Your Cummins QSC Engine?

Common signs that your QSC 8.3 engine may require a rebuild include:

-

Excessive oil consumption or visible smoke

-

Low compression readings across multiple cylinders

-

Knocking or unusual engine noises

-

Loss of power or hard starting

-

Oil in the coolant or vice versa

-

High blow-by levels and degraded piston ring seal

An overhaul with the correct rebuild kit and supporting components can restore your engine to like-new performance and extend its lifespan for years of additional service.

Rebuild Kit Selection Tips

When selecting a rebuild kit for your Cummins QSC engine:

-

Confirm the CPL number on your engine data plate.

-

Verify the piston type (one-piece or articulated).

-

Match your application (marine, stationary, or mobile equipment).

-

Replace related components like nozzles, seals, and filters to prevent early failure.

If you're unsure which kit is correct for your application, contact Diesel Pro Power’s technical team for guidance. We can help you identify your engine specs and recommend the most compatible rebuild solution.