Cummins QSB 5.9 Parts - Crankshaft Section

Loading...

Loading...-

-

-

Cummins Crankshaft Shell Set - Standard

3802070

Standard size, upper and lower bearings for complete enginePrice: $ -

Cummins Crankshaft Shell Set - 0.25

3802071

Oversize 0.25 mm, upper and lower bearings for complete enginePrice: $ -

Cummins Crankshaft Shell Set - 0.50

3802072

Oversize 0.50 mm, upper and lower bearings for complete enginePrice: $ -

-

-

Cummins Crankshaft Seal Kit - Rear

3934486

Includes the seal and sleeve, for engines with dry clutch housingPrice: $ -

Vibration Damper for Cummins engines B, ISB, QSB series

3914454

4 Bolt Holes. 8.23” Outside diameter

Price: $ -

Vibration Damper for Cummins engines B, ISB, QSB series

3918999

4 Bolt Holes, 9.7” Outside diameter

Price: $ -

Cummins Crankshaft Seal Kit - Rear

4955372

Includes the seal (double lip) and sleeve, for engines with wet clutch housingPrice: $

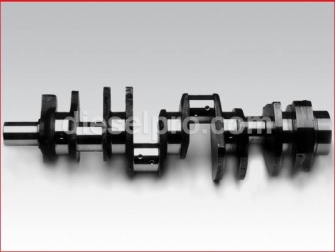

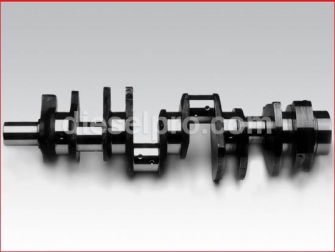

Cummins QSB 5.9L Crankshaft & Related Components

The Cummins QSB 5.9L is a proven workhorse in marine, industrial, construction, and agricultural equipment. At the heart of its performance is the crankshaft , the central rotating component that translates the pistons’ up-and-down movement into smooth, reliable rotational power.

Diesel Pro Power supplies premium aftermarket crankshafts, bearings, seals, and vibration dampers specifically designed for the QSB 5.9L platform. Each component is engineered to meet or exceed the original design specifications, ensuring dependable service life and smooth operation in even the most demanding environments. With over 40,000 satisfied customers worldwide , Diesel Pro Power has become the trusted source for QSB 5.9L rotating assembly components.

Understanding the Cummins QSB 5.9L Crankshaft

A crankshaft is more than just a piece of machined steel—it’s a highly engineered part that must endure enormous forces, maintain precise balance, and resist wear over thousands of hours of operation.

Diesel Pro Power’s premium aftermarket crankshafts for the QSB 5.9L are:

-

Manufactured from high-strength forged steel for durability.

-

Precision-machined to maintain exact bearing clearances.

-

Individually balanced to minimize vibration and protect bearings.

-

Surface-treated for enhanced wear resistance.

Applications of Diesel Pro Power Crankshafts

Our premium aftermarket crankshafts are used in a wide variety of QSB 5.9L applications, including:

-

Marine powerplants for commercial fishing vessels, tugs, and leisure craft.

-

Industrial engines for pumps, compressors, and generators.

-

Construction equipment such as excavators, cranes, and loaders.

-

Agricultural machinery including irrigation pumps and tractors.

No matter the environment, a properly maintained and balanced crankshaft is essential for protecting your QSB 5.9L from costly downtime.

Diesel Pro Power Crankshaft Product Line for QSB 5.9L

Premium Aftermarket Crankshaft – Without Timing Gear

-

Description: A brand-new, premium aftermarket crankshaft for QSB 5.9L engines, machined and balanced for immediate installation. This version is supplied without the timing gear for rebuilds where the existing gear is still in serviceable condition.

-

Advantages: Reduced cost for partial rebuilds, full compatibility with original engine configuration.

Premium Aftermarket Crankshaft Assembly – With Timing Gear

-

Description: Complete crankshaft assembly with the timing gear pre-installed for quick, error-free installation.

-

Advantages: Eliminates the need to reuse worn timing gears, ensures correct gear alignment, and saves rebuild time.

Crankshaft Bearing Shell Sets for QSB 5.9L

Crankshaft bearings are critical for reducing friction and maintaining precise crankshaft alignment. Diesel Pro Power offers complete premium aftermarket bearing sets in multiple sizes:

-

Standard Size : For crankshafts that have not been ground down.

-

0.25 mm Oversize : For crankshafts that have been ground 0.25 mm undersize.

-

0.50 mm Oversize : For crankshafts that have been ground 0.50 mm undersize.

Each bearing set includes both upper and lower shells for a complete engine installation, made with tri-metal construction for maximum load capacity and wear resistance.

Front & Rear Crankshaft Seal Kits

Oil control is critical for crankshaft longevity. Diesel Pro Power’s premium aftermarket seal kits are engineered for leak-free operation under high-load conditions.

-

Front Seal Kit with Sleeve : Ideal for restoring worn sealing surfaces.

-

Front Seal Kit with Dust Shield : Recommended for harsh environments with high dust or debris exposure.

-

Rear Seal Kit for Dry Clutch Housing: Designed for engines with dry clutch configurations.

-

Rear Seal Kit for Wet Clutch Housing : Features a double-lip design for oil-intensive environments.

Vibration Dampers for QSB 5.9L

Excessive torsional vibration is one of the most common causes of crankshaft fatigue. Diesel Pro Power’s premium aftermarket vibration dampers are precision-balanced to protect your engine’s rotating assembly.

-

8.23” Diameter Damper: Compact size for standard-duty applications.

-

9.7” Diameter Damper: Larger surface area for enhanced damping in heavy-duty service.

Best Practices for Installing Diesel Pro Power Crankshafts

When installing a new crankshaft or related component:

-

Inspect and Clean the main bearing bores.

-

Measure Precisely using a micrometer to confirm journal sizes and bearing clearances.

-

Apply Assembly Lubricant generously to all bearing surfaces.

-

Follow Torque Specifications to prevent crankshaft distortion.

-

Check End Play to ensure correct axial clearance.

-

Balance the Rotating Assembly when replacing major rotating parts.

Common Causes of Crankshaft Damage

-

Low oil pressure or inadequate lubrication.

-

Incorrect bearing clearance.

-

Overloading or overspeeding the engine.

-

Operating with a worn or defective vibration damper.

How to Extend Crankshaft Service Life

-

Use Diesel Pro Power premium aftermarket crankshafts, bearings, and seals for every rebuild.

-

Change oil and filters at recommended intervals.

-

Replace vibration dampers as part of preventive maintenance.

-

Inspect seal surfaces regularly for wear.