Cummins NH855 Engine Parts - Camshaft Section

Loading...

Loading...-

-

-

-

-

-

-

Push Rod for Cummins Valve Rocker | 855 NH | NT

3046420

Requires 12per Big Cam Engine

Price: $ 23.22 -

Push Rod for Cummins Injector Rocker 855 NH and NT

3046430

Requires 6per Big Cam Engine

Price: $ 23.22 -

Push Rod for Cummins Injector Rocker for 855 NH and NT engines

3046431

Requires 6 per Small Cam EnginePrice: $ 27.50

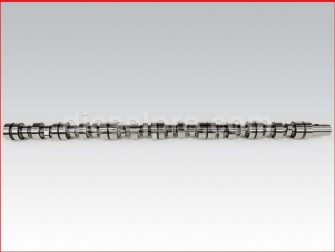

Cummins NH855 Camshaft and Valve Train Components

The Cummins NH855 engine has been a workhorse in heavy-duty, industrial, and marine applications for decades. At the heart of its performance lies the camshaft—a critical component that ensures proper timing of the intake, compression, power, and exhaust strokes. Whether you are working on an older 855 Small Cam engine or a later 855 Big Cam, maintaining a healthy camshaft and valve train system is essential for reliability, efficiency, and long-term durability.

This section covers everything you need to know about camshafts and related components for the NH855, including bushings, seals, and push rods designed to keep your engine running at peak performance.

Camshafts for Cummins NH855 Engines

Small Cam (Flangeless) Camshaft

The Small Cam NH855 camshaft is designed for earlier models of the engine, commonly referred to as “flangeless” designs. These camshafts are precision-engineered to control valve timing accurately, ensuring optimal fuel combustion and power output.

Key benefits of the Small Cam camshaft include:

-

Reliable performance in demanding industrial and marine environments.

-

Durable metallurgy designed to withstand high loads and long service intervals.

-

Flangeless configuration compatible with early NH and NT engine blocks.

Big Cam (Flangeless) Camshaft

The Big Cam camshaft was introduced as part of Cummins’ improvements to the 855 series. With revised timing and airflow optimization, the Big Cam design provided greater fuel efficiency and lower emissions compared to the Small Cam predecessor.

Benefits of the Big Cam camshaft include:

-

Improved engine breathing for better power delivery.

-

Compatibility with later-generation NH855 and NT855 engines.

-

Built to OEM specifications for proper fit and function.

Supporting Components for the Camshaft Assembly

The camshaft doesn’t operate in isolation. Several key components support its function within the Cummins NH855 valve train system.

Camshaft Bushing Set (Big Cam Engines)

The camshaft bushing set provides the smooth, low-friction surface that allows the camshaft to rotate freely under heavy loads. For Big Cam engines, a full set is required to service the entire engine. Replacing worn bushings during a rebuild helps:

-

Maintain proper oil clearance for the camshaft journals.

-

Reduce friction and wear.

-

Ensure quiet, efficient camshaft operation.

Accessory Drive Cover Oil Seal

The accessory drive cover oil seal prevents oil leakage where the camshaft or accessory drive passes through the timing cover. A properly installed seal protects against contamination, preserves oil pressure, and extends the service life of the camshaft bearings.

Fan Hub Oil Seal

The fan hub oil seal serves a similar purpose, preventing oil leaks in the forward section of the engine. On NH855 and NT855 engines, maintaining this seal ensures consistent lubrication for the camshaft and related front-end components.

Bushing for Driver Support

The driver support bushing stabilizes the camshaft and accessory drive components. A worn bushing can lead to excess vibration, uneven wear, and eventual misalignment of the camshaft. Replacing this inexpensive but critical part during a rebuild helps maintain camshaft stability under load.

Push Rods for Cummins NH855

The push rods transmit motion from the camshaft lobes to the rocker arms, which then actuate either the intake/exhaust valves or the injectors. Because of the design differences between Small Cam and Big Cam NH855 engines, specific push rods are required depending on the version of the engine.

Valve Rocker Push Rods

-

Used on both Small Cam and Big Cam versions.

-

Typically, 12 push rods are required per Big Cam engine to operate all intake and exhaust valves.

-

Designed to resist bending and wear under continuous heavy-duty use.

Injector Rocker Push Rods

-

Separate push rods are used for injector operation.

-

Big Cam engines require six injector push rods.

-

Small Cam engines also require six injector push rods, but the design differs slightly from the Big Cam version.

-

Replacing injector push rods ensures precise fuel delivery timing, which is essential for maintaining power and efficiency.

Why Proper Camshaft Maintenance Matters

Neglecting the camshaft and related valve train components in an NH855 engine can lead to:

-

Loss of power due to poor valve timing.

-

Increased fuel consumption from inefficient combustion.

-

Premature wear on valves, rocker arms, and injectors.

-

Oil leaks that compromise lubrication and increase contamination.

Routine inspection and replacement of camshaft bushings, seals, and push rods during major service or overhauls help extend the engine’s life and preserve its legendary durability.

Diesel Pro Power Advantage

Diesel Pro Power supplies OEM-quality camshafts and valve train components for Cummins NH855 and NT855 engines, ensuring that you receive parts designed for long-lasting reliability. With over 40,000 satisfied customers worldwide , we’ve built our reputation on delivering dependable parts, fast shipping, and expert support for heavy-duty diesel engines.