Cummins 6B Engine Parts

-Select Parts Category

Loading...

Loading...- 1

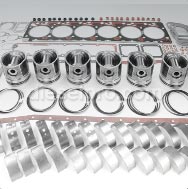

Engine Overhaul Kit

Engine Overhaul Kit - 2

Cylinder Head

Cylinder Head - 3

Injector

Injector - 4

Fuel Pump

Fuel Pump - 5

Engine Water Pump

Engine Water Pump - 6

Marine Water Pump

Marine Water Pump - 7

Oil Pump

Oil Pump - 8

Gauge

Gauge - 9

Crankshaft

Crankshaft - 10

Camshaft

Camshaft - 11

Piston Kit

Piston Kit - 12

Connecting Rod

Connecting Rod - 13

Exhaust

Exhaust - 14

Gasket

Gasket - 15

Sensor

Sensor - 16

Switch

Switch - 17

Manuals & Tools

Manuals & Tools - 18

Starter & Alternator

Starter & Alternator - 19

Hose, Clamp

Hose, Clamp - 20

Fuel Filter

Fuel Filter - 21

Oil Filter

Oil Filter - 22

33C Marine Cable (3/16")

33C Marine Cable (3/16") - 23

43C Marine Cable (1/4")

43C Marine Cable (1/4") - 24

Industrial Cable

Industrial Cable - 25

Paint & Sealant

Paint & Sealant

Parts for Cummins 6B Engines

Premium Cummins 6B Marine and Industrial Engine Parts from Diesel Pro Power

The Cummins 6B engine —also referred to as the 6BT—is a workhorse in the world of diesel power. With a 5.9L inline-six configuration, mechanical fuel injection, and robust construction, it has been widely adopted in marine propulsion systems, industrial generators, irrigation setups, and hydraulic drive applications. But to maintain the legendary reliability and performance Cummins engines are known for, only the right parts will do .

At Diesel Pro Power, we’re proud to offer a full range of high-quality, marine-grade and industrial-spec Cummins 6B parts, ready to ship worldwide in just 24 hours. Whether you’re rebuilding an engine or replacing a worn-out water pump on your vessel or stationary unit, we deliver fast, trusted service and expert support.

We serve professional operators, marine technicians, industrial maintenance teams, shipyards, and government agencies with fast, global delivery and personalized customer care. From top-end kits to precision fuel parts, Diesel Pro Power is your one-stop shop for Cummins 6B parts.

Buy Cummins 6B Parts Online – Accurate, Fast & Global

Shop a Complete Selection of 6B Engine Parts

We carry one of the most complete inventories of Cummins 6B parts available online, with every component selected to withstand the demands of continuous-duty marine and industrial applications. All parts are vetted for compatibility with 6B, 6BT, and 6BTA mechanical configurations.

Fresh Water Pumps for Cummins 6B

Our fresh water pumps are engineered to circulate coolant through closed-loop marine or industrial systems such as heat exchangers or keel coolers. These pumps are ideal for 6B engines operating in:

-

Marine propulsion systems

-

Gensets onboard commercial vessels

-

Hydraulic power units with closed cooling loops

Features:

-

Heavy-duty cast iron housings

-

Sealed bearings for longer service life

-

Compatibility with standard fan belts

-

Optional pulley kits and belt tensioners

-

Covered by a one-year warranty

We also carry related accessories such as:

-

Silicone coolant hoses

-

Thermostat assemblies

-

Expansion tank fittings and gaskets

Sea Water Pumps for Cummins 6B

Diesel Pro Power supplies raw water (sea water) pumps specifically designed for marine Cummins 6B installations. These pumps play a critical role in drawing in seawater to cool engine components or heat exchangers.

Key features:

-

Bronze marine-grade construction

-

Long-life impellers and wear-resistant seals

-

Bolt-on installation with optional bracket kits

You’ll also find:

-

Pump repair kits

-

Impellers

-

Zinc anodes

-

Raw water strainers

-

Gaskets and mounting bolts

These pumps are essential in protecting your engine from overheating and are recommended for preventative replacement every season in saltwater environments.

Connecting Rods for Cummins 6B

Our connecting rod assemblies are available in matched sets and include:

-

Lower and upper rod bearings

-

Standard and oversize options

-

High-load ratings for continuous-duty operation

These components are crucial for maintaining smooth piston travel and preventing engine knock or bearing failure—especially under high-torque conditions found in marine propulsion or industrial applications like pumps and compressors.

Cylinder Heads for Cummins 6B

We offer fully assembled cylinder heads for Cummins 6B engines, featuring:

-

New valves, valve springs, guides, and seals

-

Precision-machined injector tubes

-

Pressure testing for leak-free performance

Accessories include:

-

Cylinder head bolts

-

Push rods

-

Rocker arm assemblies

-

Valve cover gaskets

Ideal for rebuilds following head warpage, overheating, or excessive blow-by, our 6B heads are designed to drop in and restore factory compression and performance .

Engine Overhaul Kits for Cummins 6B

Whether you're planning scheduled maintenance or recovering from a failure, our 6B engine rebuild kits offer a complete solution. These kits include:

-

Pistons and piston rings

-

Main and rod bearings

-

Upper and lower gasket sets

-

Valve train seals

-

Oil seals

-

Thrust washers

We stock standard and oversize kits to accommodate cylinder wear or journal polishing. Rebuild kits are packaged for:

-

Marine 6B propulsion engines

-

Industrial 6B generators

-

Hydraulic power units or pump engines

Fuel System Components for Cummins 6B

Fuel delivery must be precise for optimal performance. Our 6B fuel system parts include:

-

Mechanical fuel injectors

-

Injector nozzles and seals

-

Injection pumps

-

Fuel lift pumps

-

Fuel filter heads and spin-on filters

-

Injector return lines

Each injector and pump is built to OEM specs, with marine fuel blend compatibility and corrosion resistance. Proper injector maintenance prevents power loss, white smoke, or uneven combustion.

Oil System Components for Cummins 6B

Oil circulation is vital for engine longevity. We carry full oil system support for 6B Cummins, including:

-

Oil filters and filter bases

-

Oil coolers and seals

-

Oil pressure switches and sensors

-

Oil pumps and pickup assemblies

-

Drain plugs and pan gaskets

Built for extended-duty schedules and extreme operating temperatures, these components ensure proper lubrication of internal parts and protect against premature wear.

Starters, Alternators, and Electrical Components for Cummins 6B

Diesel Pro Power supplies:

-

12V and 24V starters

-

Marine-grade alternators

-

Glow plug and pre-heat systems (for cold weather)

-

Engine sensors: temperature, RPM, oil pressure

-

Wiring harnesses and relay panels

All electrical components are waterproof and vibration-tested for marine use. Need a specific solenoid or bracket? We have you covered.

Additional Cummins 6B Parts We Offer

We also stock:

-

Engine mounts and vibration isolators

-

Gasket kits (top, bottom, and full sets)

-

Thermostats and temperature switches

-

Marine control cables

-

Exhaust elbows and risers

-

Belt kits and pulleys

-

Air filters and intake manifolds

-

Turbochargers and related hardware (for 6BTA variants)

Why Buy Your 6B Cummins Parts From Diesel Pro Power?

Global Reach with Local-Level Service

We support diesel professionals and operators around the world with parts that ship out within 24 hours . Our warehouse stocks thousands of parts ready for same-day fulfillment.

15,000+ Satisfied Customers

With decades in business and thousands of global customers—from commercial fishing fleets to remote mining camps—we’ve built trust through reliable service, fast shipping, and helpful guidance.

Secure and Simple Ordering

-

User-friendly website with accurate parts search

-

Secure payment portal with encryption

-

Prepaid duty and tax options for international buyers

-

Multilingual customer service available

Unmatched Technical Support

Need help selecting the correct piston oversize? Unsure whether a marine head gasket is thicker than industrial? Our team of diesel experts can guide you based on your engine serial number or CPL .

Cummins 6B Applications: Built for Work, Not Commute

The 6B is a preferred powerplant in a variety of heavy-duty scenarios:

Marine Applications

-

Commercial fishing vessels

-

Towboats and tugboats

-

Pilot boats and patrol craft

-

Onboard auxiliary gensets

-

Bilge, fire, and hydraulic pumps

Industrial Applications

-

Power generation sets for hospitals, data centers, and plants

-

Irrigation and water pumping stations

-

Compressor systems for mining and manufacturing

-

Concrete mixing plants and sawmill engines

-

Hydraulic drive systems for cranes and presses

These environments demand engines that run for hours or days on end—and the Cummins 6B delivers.

Maintenance Tips for Marine and Industrial Cummins 6B Engines

Marine Preventative Maintenance

-

Replace seawater impellers every 100 hours or annually

-

Inspect zinc anodes quarterly and replace if 50% degraded

-

Flush heat exchangers regularly to remove scaling

-

Check coolant PH and use marine-approved antifreeze

-

Grease marine throttle and shift cables

Industrial Maintenance Routine

-

Replace oil and fuel filters every 250–300 hours

-

Clean air filters regularly in dusty sites

-

Inspect belts and coolant hoses monthly

-

Keep detailed logbooks of run time

-

Test coolant and oil pressure sensors every 500 hours

Recommended Replacement Intervals

| Component |

Marine Use |

Industrial Use |

|---|---|---|

| Oil Filter |

Every 150–200 hours |

Every 250 hours |

| Fuel Filter |

Every 100–150 hours |

Every 200 hours |

| Raw Water Impeller |

Every 100 hours or annually |

N/A |

| Zinc Anodes |

Every 3–6 months |

N/A |

| Thermostat |

Every 2 years |

Every 2 years |

| Cylinder Head |

As needed (overheating) |

As needed |

| Injectors |

Every 3,000 hours |

Every 4,000 hours |

| Belts |

Every 2 years |

Every 2 years |

| Fresh Water Pump |

Every 2–3 years |

Every 3–4 years |

Order Cummins 6B Parts Online or Call Our Experts Today

Place your order today and receive:

-

Worldwide shipping within 24 hours

-

OEM-quality parts at competitive prices

-

Expert technical guidance for every order

Contact Diesel Pro Power

-

Phone (US & Canada): 1-888-433-4735

-

International: +1-305-545-5588

-

Hours: Monday–Friday, 8 AM–5 PM EST

-

Email: Contact us via our website with your engine details

Whether you’re running a portside generator or refitting a commercial vessel, we’ll make sure you get the right parts, fast .

Engine Specifications & Applications of the Cummins 6B Engine

Overview of the Cummins 6B Engine

The Cummins 6B is a naturally aspirated, inline six-cylinder diesel engine that laid the foundation for one of the most respected engine platforms in industrial and marine applications. As the predecessor to the better-known 6BT and 6BTA engines, the 6B is a simplified, turbo-free version of the 5.9L B Series platform, ideal for low-maintenance, continuous-duty roles. With no turbocharger or intercooler, the 6B engine emphasizes simplicity, reliability, and steady torque delivery , making it especially attractive to users who require maximum uptime in demanding environments.

First introduced in the early 1980s, the 6B has seen long-standing service in power generation, marine support systems, agricultural equipment, construction platforms, and oilfield utility machinery . Its mechanical injection system and lack of electronic components make it ideal for remote installations, export applications, and non-emissions markets .

Cummins 6B Engine Specifications

| Specification |

Detail |

| Configuration |

Inline 6-cylinder, 4-stroke diesel |

| Displacement |

5.9 liters (359 cubic inches) |

| Bore x Stroke |

4.02 in x 4.72 in (102 mm x 120 mm) |

| Aspiration |

Naturally Aspirated |

| Fuel System |

Mechanical direct injection (Bosch rotary or inline pump) |

| Compression Ratio |

17.5:1 |

| Horsepower Range |

80–120 HP @ 2,500–2,800 RPM |

| Peak Torque |

230–320 lb-ft @ 1,600–1,800 RPM |

| Cooling System |

Liquid-cooled with belt- or gear-driven water pump |

| Oil Capacity |

15–16 quarts (14–15 liters) |

| Dry Weight |

950–1,050 lbs (431–476 kg) |

| Flywheel Housing |

SAE #2 or #3 |

| Emissions Tier |

Pre-Tier 1 (Non-Electronic) |

| Valvetrain |

OHV (Overhead Valve) with 2 valves per cylinder |

| Service Life (Rebuild) |

10,000–15,000+ hours with proper maintenance |

The 6B was engineered to withstand harsh operating conditions while maintaining low operating costs. With fewer moving parts than turbocharged variants, the 6B delivers consistent performance and ease of servicing , making it ideal for remote locations and legacy equipment operators.

Common Applications of the Cummins 6B Engine

Due to its balance of power, mechanical simplicity, and rugged construction, the Cummins 6B is used in a wide range of applications. It particularly excels in steady-state or low-RPM operations , where load predictability and uptime are critical. From backup generators to agricultural irrigation engines, the 6B provides reliable performance with minimal complexity.

1. Marine Auxiliary and Generator Applications

Although the 6B is not commonly used for primary marine propulsion, it is a proven performer in auxiliary systems aboard commercial and work vessels. Its smooth torque curve and naturally aspirated design make it a preferred power source for systems that require long-duration runtime with low maintenance needs .

Marine Applications Include:

-

Onboard diesel generator sets (40–80 kW range)

-

Fire pump engines

-

Desalination pump drives

-

Hydraulic system support (winches, cranes)

-

Refrigeration compressor engines

-

Fuel transfer and bilge pumping systems

With no turbocharger or intercooler, the 6B handles marine engine room conditions well— less heat, fewer components to fail , and lower risk of performance degradation due to salt or humidity exposure.

2. Industrial and Commercial Generator Systems

In the world of stationary power generation , the Cummins 6B is a workhorse. Whether used as a backup system or a prime power engine, it is appreciated for fuel economy, mechanical reliability, and consistent performance at fixed RPMs.

Generator Use Cases:

-

Remote-site generators (construction camps, farms, rural homes)

-

Emergency backup gensets (commercial or industrial buildings)

-

Continuous duty power for communication towers

-

Utility and grid-tied standby power plants

-

Mobile generator trailers and skids

Operators prefer the 6B for its ease of starting, simplicity of integration , and long overhaul intervals—especially in settings where electronic controls would be a liability.

3. Agricultural Equipment

The Cummins 6B is highly suitable for use in farm and irrigation systems , especially in parts of the world where Tier 4 compliance is not required. Its six-cylinder design offers a balance of smooth operation and steady torque ideal for rotational or pumping duties .

Agricultural Use Cases:

-

Diesel-powered irrigation systems

-

Grain augers and dryers

-

Skid-mounted pumps

-

Feed mixers and milling equipment

-

Repower engines for older tractors and combines

Its naturally aspirated airflow makes the 6B well suited for environments with high dust or particulate matter, reducing maintenance compared to turbocharged models.

4. Construction & Material Handling Equipment

Though more commonly replaced by newer 6BT and 6BTA variants, the 6B still powers many legacy construction and utility machines around the world.

Equipment Examples:

-

Wheel loaders and small dozers

-

Aerial work platforms and boom lifts

-

Skid-mounted compressors and generators

-

Utility trenchers and ground prep tools

-

Light-duty cranes or lifting hoists

In these machines, the 6B’s simplicity is key: fewer sensors, no turbo-related pressure or heat concerns, and predictable RPM behavior under varying load .

5. Oilfield and Utility Power Units

In the oil and gas sector, the 6B serves as a standalone utility engine for non-propulsion systems. Its predictable fuel consumption and mechanical durability make it well-suited for both temporary and permanent field installations.

Common Use Cases:

-

Mud mixing pump drives

-

Utility skid engines for lighting, compressors, or fluid transfer

-

Fuel pump drives for refueling operations

-

Winch and hydraulic power units

-

Oilfield monitoring system engines

The 6B’s non-electronic fuel system also simplifies integration with manual controls, relays, and pressure switches commonly used in these sectors.

6. Export and International Repower Applications

Because of its mechanical design and lack of emissions restrictions, the 6B remains in high demand for export markets and equipment repowering in developing regions.

Global Applications:

-

Generator exports to Latin America, Africa, and Asia

-

Agricultural machinery in non-regulated markets

-

Refurbished marine support engines

-

Engine swaps in legacy industrial machines

-

Repower projects for off-road and rail equipment

Its parts compatibility with the entire B Series family ensures continued support even in remote regions, and its long lifecycle keeps cost of ownership low over time.

Why Choose the Cummins 6B?

The 6B remains a trusted diesel platform for users who prioritize:

-

Mechanical Reliability – No ECUs, no emissions hardware, just proven direct injection and analog controls.

-

Ease of Servicing – Rebuildable in the field using widely available kits and basic tools.

-

Fuel Efficiency – Optimized for long, steady-duty cycles at moderate RPM.

-

Durability – Cast iron block and head, robust bottom end, long overhaul intervals.

-

Uptime – Fewer failure points and simpler operation compared to turbocharged alternatives.

-

Low Total Cost of Ownership – Lower initial cost, rebuildability, and affordable maintenance.

-

Ideal for Harsh Environments – Performs well in dusty, salty, or humid locations with minimal filtration needs.

Conclusion

The Cummins 6B engine offers a rugged, naturally aspirated alternative to turbocharged diesel platforms, making it ideal for marine auxiliary systems, industrial generators, agricultural equipment, and utility machines. With no electronics and no forced induction, the 6B represents a return to simple, reliable diesel power .

For operators in challenging environments, or for those maintaining older equipment in regions where emissions standards are not enforced, the 6B provides a dependable, low-maintenance solution. When paired with the right aftermarket support, this engine can easily exceed 15,000 hours of service—often with just routine maintenance and a midlife overhaul.

A dditional Resources

A Step-by-Step Guide to Installing a Cummins 6B Sea Water Pump

Guide To Buying A Cummins 6B Overhaul Kit

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

FAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction - Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines