Cummins ISB 5.9 Parts

-Select Parts Category

Loading...

Loading...- 1

Rebuild Kit

Rebuild Kit - 2

Gauge

Gauge - 3

Engine Water Pump

Engine Water Pump - 4

Cylinder Head

Cylinder Head - 5

Fuel Pump & Injector

Fuel Pump & Injector - 6

Turbo

Turbo - 7

Oil

Oil - 8

Crankshaft

Crankshaft - 9

Camshaft

Camshaft - 10

Piston Kit

Piston Kit - 11

Connecting Rod

Connecting Rod - 12

Exhaust

Exhaust - 13

Gasket

Gasket - 14

Sensor

Sensor - 15

Switch

Switch - 16

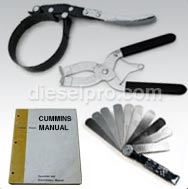

Manual & Tools

Manual & Tools - 17

Starter & Alternator

Starter & Alternator - 18

Hose, Clamp

Hose, Clamp - 19

Fuel Filter

Fuel Filter - 20

Oil Filter

Oil Filter - 21

33C Marine Cable (3/16")

33C Marine Cable (3/16") - 22

43C Marine Cable (1/4")

43C Marine Cable (1/4") - 23

Industrial Cable

Industrial Cable - 24

Paint, More

Paint, More

Parts For Cummins ISB 5.9 Industrial Engines

The Cummins ISB 5.9 engine is renowned for its durability and performance in various applications, including marine and industrial settings. At Diesel Pro Power, we offer a wide selection of high-quality parts to ensure your engine operates at peak efficiency. With our 24-hour worldwide shipping, you can count on us to deliver the components you need promptly, no matter where you are.

Understanding the Cummins ISB 5.9 Engine

Engine Overview

The Cummins ISB 5.9 is a 5.9-liter, inline six-cylinder diesel engine known for its robust construction and reliable performance. Key features include:

-

24-Valve Configuration : Enhances airflow and combustion efficiency

-

Electronically Controlled Fuel Injection : Provides precise fuel delivery

-

Turbocharging : Improves power output and fuel efficiency

-

Cast-Iron Block and Cylinder Head : Offers strength and durability for long-term use

This engine is widely used in trucks, buses, marine vessels, and industrial equipment.

Extensive Selection of Parts for Cummins ISB 5.9

At Diesel Pro Power, we provide a comprehensive range of components for Cummins ISB 5.9 engines, carefully selected to support long-term performance, simplified maintenance, and reliable power output.

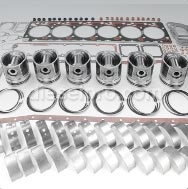

Engine Rebuild Kits for Cummins ISB 5.9

Our engine rebuild kits are designed to restore your engine to its original performance standards. Options include:

-

Complete overhaul kits

-

Top-end rebuild kits

-

Bottom-end kits

-

Seal kits

Each kit is built to OEM specifications, ensuring proper fitment and optimal engine performance.

Fresh Water Pumps for Cummins ISB 5.9

Maintaining proper operating temperature is crucial. Our inventory includes:

-

Pump assemblies

-

Thermostat seals and pump seals

-

Pump belts

These cooling system parts help keep your engine running cool and efficient.

Cylinder Heads for Cummins ISB 5.9

Cylinder head service is essential for valve function and combustion efficiency. Our offerings include:

-

Fully assembled cylinder heads

-

Valves and springs

-

Gaskets

Replacing or refurbishing your cylinder head components ensures fuel economy and power consistency.

Fuel Pumps and Fuel System Parts for Cummins ISB 5.9

We offer a full lineup of parts to keep your fuel system clean and efficient:

-

Fuel pumps

-

Fuel and water separator filters

-

Injection pump gaskets

These items help ensure that fuel delivery remains clean, precise, and leak-free.

Crankshafts for Cummins ISB 5.9

The crankshaft drives all engine motion. Our selection includes:

-

Crankshafts

-

Main and rod bearings

-

Thrust washers

These rotating components are essential for smooth operation and reduced engine wear.

Camshafts for Cummins ISB 5.9

Precise valve timing begins with a reliable camshaft system. We offer:

-

Camshafts

-

Timing gears

-

Camshaft bearings

A properly functioning cam system boosts power, efficiency, and emissions control.

Gauges and Sensors for Cummins ISB 5.9

Keep a close eye on your engine’s health with our monitoring solutions:

-

Oil pressure gauges

-

Water temperature gauges

-

Tachometers and voltage gauges

These gauges are marine-rated and help ensure proactive maintenance.

Alternators and Electrical Components for Cummins ISB 5.9

A stable power supply is critical for engine management and onboard systems. Our selection includes:

-

Alternators

-

Starter motors

-

Wiring harnesses

These components help ensure dependable starts and electrical continuity.

Common Applications of the Cummins ISB 5.9

The versatility of the Cummins ISB 5.9 engine allows it to excel in:

Marine Applications

-

Commercial vessels

-

Recreational boats

-

Marine generators

Industrial Applications

-

Construction equipment

-

Agricultural machinery

-

Stationary power systems

Understanding your application ensures proper part selection and maintenance planning.

Maintenance Tips for ISB 5.9 Longevity

Oil & Filter System

-

Change oil and filters regularly

-

Use manufacturer-recommended oil type

Cooling System

-

Flush coolant as recommended

-

Inspect belts, hoses, and seals frequently

Fuel System

-

Replace fuel and water separator filters regularly

-

Inspect fuel lines and gaskets for leaks

Electrical System

-

Test battery voltage and connections

-

Inspect and replace worn alternators or starters

A proactive maintenance plan helps reduce repair costs and maximize uptime.

Why Choose Diesel Pro Power for Cummins ISB 5.9 Parts

-

24-hour worldwide shipping

-

More than 40,000 satisfied global customers

-

Expert assistance from real diesel engine professionals

-

Full inventory of hard-to-find and marine-grade components

-

Easy-to-use online catalog

We’re more than just a parts provider—we’re your long-term engine support partner.

Engine Specifications & Applications of the Cummins ISB 5.9 Engine

Introduction

The Cummins ISB 5.9 is one of the most trusted mid-range diesel engines in the world, widely used across marine, construction, industrial, and generator applications. As the electronically controlled successor to the legendary mechanical 6BT, the ISB 5.9 brought significant advancements in fuel injection, emissions control, and engine management while preserving the platform’s core strengths: reliability, simplicity, and serviceability .

Developed in the late 1990s and produced well into the 2000s, the ISB 5.9 features high-pressure common rail (HPCR) fuel injection , a turbocharged and aftercooled design , and full-authority electronic control , making it a highly adaptable platform for Tier 2 and Tier 3 emissions-regulated environments. Whether in a marine genset, a skid-mounted industrial unit, or a mobile hydraulic power pack, the ISB 5.9 remains a top choice for operators looking for robust performance and long-term value in demanding settings.

Cummins ISB 5.9 Engine Specifications

| Specification |

Detail |

| Configuration |

Inline 6-cylinder, 4-stroke diesel |

| Displacement |

5.9 liters (359 cubic inches) |

| Bore x Stroke |

4.02 in x 4.72 in (102 mm x 120 mm) |

| Aspiration |

Turbocharged and Aftercooled |

| Fuel System |

High-Pressure Common Rail (HPCR) / Bosch VP44 |

| Compression Ratio |

17.2:1 |

| Horsepower Range |

175–325 HP @ 2,500–2,900 RPM |

| Peak Torque |

460–600 lb-ft @ 1,400–1,600 RPM |

| Cooling System |

Liquid-cooled with belt-driven water pump |

| Lubrication Capacity |

15–17 quarts (14–16 liters) |

| Dry Weight |

~1,100 lbs (499 kg) |

| Emissions Certification |

Tier 2 / Tier 3 (depending on model year) |

| Valvetrain |

OHV, 4 valves per cylinder |

| ECM |

Full-authority, CAN-bus capable |

The ISB 5.9 engine maintained many design features of the original 6BT—such as its gear-driven camshaft and forged-steel crankshaft—but introduced electronic controls and higher fuel injection pressures, improving both efficiency and emissions performance. Many versions also included an exhaust gas recirculation (EGR) system to comply with U.S. EPA regulations.

Notable Features of the Cummins ISB 5.9

-

High-Pressure Fuel Injection : Delivers better atomization, more complete combustion, and lower soot output.

-

Electronic Control Module (ECM) : Enables precise fuel metering, real-time diagnostics, and compatibility with modern control systems.

-

Built for Emissions Compliance : Tier 2 and Tier 3 ready, ideal for regulated markets and environmentally sensitive applications.

-

Turbocharging & Aftercooling : Supports high power output with improved thermal efficiency and response under load.

-

Wide Parts Availability : Shares many components with the mechanical B Series and later ISB engines, simplifying aftermarket service.

-

Service-Friendly : Built for ease of access with durable components and long service intervals.

Industrial and Marine Applications of the ISB 5.9

The Cummins ISB 5.9 engine has been adopted in thousands of applications across a wide spectrum of commercial and industrial sectors. Its combination of reliable power, compact footprint, and modern control makes it particularly valuable for aftermarket repowers, industrial system upgrades, and export-ready machines.

1. Marine Generator and Auxiliary Systems

The ISB 5.9’s compact size, turbocharged performance, and ECM-based controls make it a go-to engine for marine generator sets and auxiliary equipment requiring reliable, emissions-friendly diesel power.

Common Marine Applications:

-

Diesel generator sets for commercial vessels and yachts

-

Hydraulic pump engines for winches, cranes, and deck gear

-

Fire pump engines meeting SOLAS and ABS standards

-

Utility engines for bilge, HVAC, and refrigeration support systems

In marine environments where Tier 2/3 emissions are mandated , the ISB 5.9 offers a ready-to-install solution with minimal retrofitting. It is also frequently used in repowers of aging marine gensets originally powered by mechanical 6BT engines.

2. Industrial Generator Sets

The ISB 5.9 is a popular powerplant for stationary and portable gensets operating between 80 and 150 kW . It offers fuel efficiency, clean emissions, and stable power output across a wide range of conditions.

Typical Generator Applications:

-

Standby generators for hospitals, schools, and industrial plants

-

Prime power in remote job sites, camps, and mining operations

-

Mobile gensets on trailers or skids for construction

-

Export generators for emissions-regulated markets

Its ECM allows for governor programming, load management, and telematics integration , making it ideal for today’s smart grid and remote power infrastructure.

3. Construction & Off-Road Equipment

The ISB 5.9 was widely used in construction machinery during its production life, especially in mid-2000s Tier 2/Tier 3 era equipment. It remains in service in many machines still operating today and is a common target for aftermarket overhauls.

Equipment Types:

-

Skid steers, small excavators, and loaders

-

Utility trucks and service vehicles

-

Light paving machines and compactors

-

Boom lifts, scissor lifts, and material handlers

For aftermarket rebuilders, the ISB 5.9’s standardized mounts and modular components make it easier to swap into older equipment needing emissions upgrades or more reliable fuel control.

4. Agricultural Machinery and Diesel Pumps

The ISB 5.9 continues to serve in stationary and mobile farm power units , thanks to its fuel economy, straightforward diagnostics, and emissions-ready architecture.

Agriculture Use Cases:

-

Diesel irrigation pump power units

-

Grain dryers, augers, and conveyor drives

-

Gensets for poultry and livestock facilities

-

Tractors and sprayers in mid-size farming operations

Its broad torque band and efficient fuel usage make the ISB 5.9 particularly suitable for intermittent, high-load farm applications in regions with Tier 2 or Tier 3 regulatory frameworks.

5. Oilfield and Utility Power Units

The ISB 5.9 has found a strong foothold in oilfield and industrial utility roles , powering equipment where space and emissions compliance matter just as much as torque.

Oilfield/Utility Roles:

-

Light-duty frac pump support engines

-

Portable light towers and welding machines

-

Instrumentation trailers and environmental monitoring skids

-

Mobile workshops and fuel transfer systems

Because it operates well in hot, dusty environments and supports real-time engine monitoring , the ISB 5.9 is ideal for continuous-duty work in oilfields, pipelines, and field repair centers.

Aftermarket Advantages of the ISB 5.9

Diesel Pro Power supports thousands of Cummins ISB 5.9 owners and rebuilders with OEM-grade and aftermarket components. Key benefits of using or repowering with the ISB 5.9 include:

-

Emissions Readiness : Meets Tier 2/3 standards for use in North America, Europe, and select regulated countries.

-

High Torque at Low RPM : Ensures stable performance under heavy loads, ideal for hydraulic and generator systems.

-

Easy Integration : Shared mounting points with earlier 6BT models make it simple to retrofit in older installations.

-

Electronic Control : Allows operators to remotely monitor, control, and service the engine using modern tools.

-

Service Life : With regular maintenance, the ISB 5.9 often exceeds 10,000–15,000 hours before needing a major overhaul.

-

Abundant Parts Availability : Supported by a wide global supply chain for both new and remanufactured parts.

Whether rebuilding a marine genset, upgrading a field pump, or replacing an older Tier 1 engine, the ISB 5.9 delivers the ideal combination of power, reliability, and emissions compliance for the aftermarket diesel industry.

Conclusion

The Cummins ISB 5.9 engine stands at the intersection of old-school durability and new-age diesel technology. It represents one of the most significant upgrades from the mechanical B Series platform, integrating full electronic control and high-pressure fuel injection without compromising the core performance traits that made Cummins a household name in diesel power.

Trusted in thousands of installations worldwide, the ISB 5.9 continues to serve marine and industrial users who demand compact power, emissions compliance, and proven reliability . Whether you’re repowering an auxiliary generator on a vessel or outfitting a mobile construction unit, this engine offers a scalable and cost-effective solution for long-term operation in demanding environments.